Join our project email list

Click here to start receiving news and updates on EWEB's College Hill Reservoir improvement project.

Controlled drilling and blasting is necessary to loosen and fragment rock materials to a size that can be removed, transported, or crushed from the College Hill site. EWEB is working with a qualified contractor for the controlled drilling and blasting on this project. The contractor has reviewed the geology of the site and has determined controlled drilling and blasting can be accomplished within thresholds for ground vibration and air overpressure adopted by the Oregon State Fire Marshal in the National Fire Protection Association (NFPA) 495 standards. These standards were adopted to ensure the protection of properties near blast sites.

Explore this webpage: Why we are Using Controlled Drilling and Blasting | Regulatory Framework, Blast Design, and Safeguards to Protect Existing Structures | Videos of Blasting from a Similar Project | Geotechnical Investigation and Seismic Hazard Study | Other Frequently Asked Questions

Why we are Using Controlled Drilling and Blasting for this Project

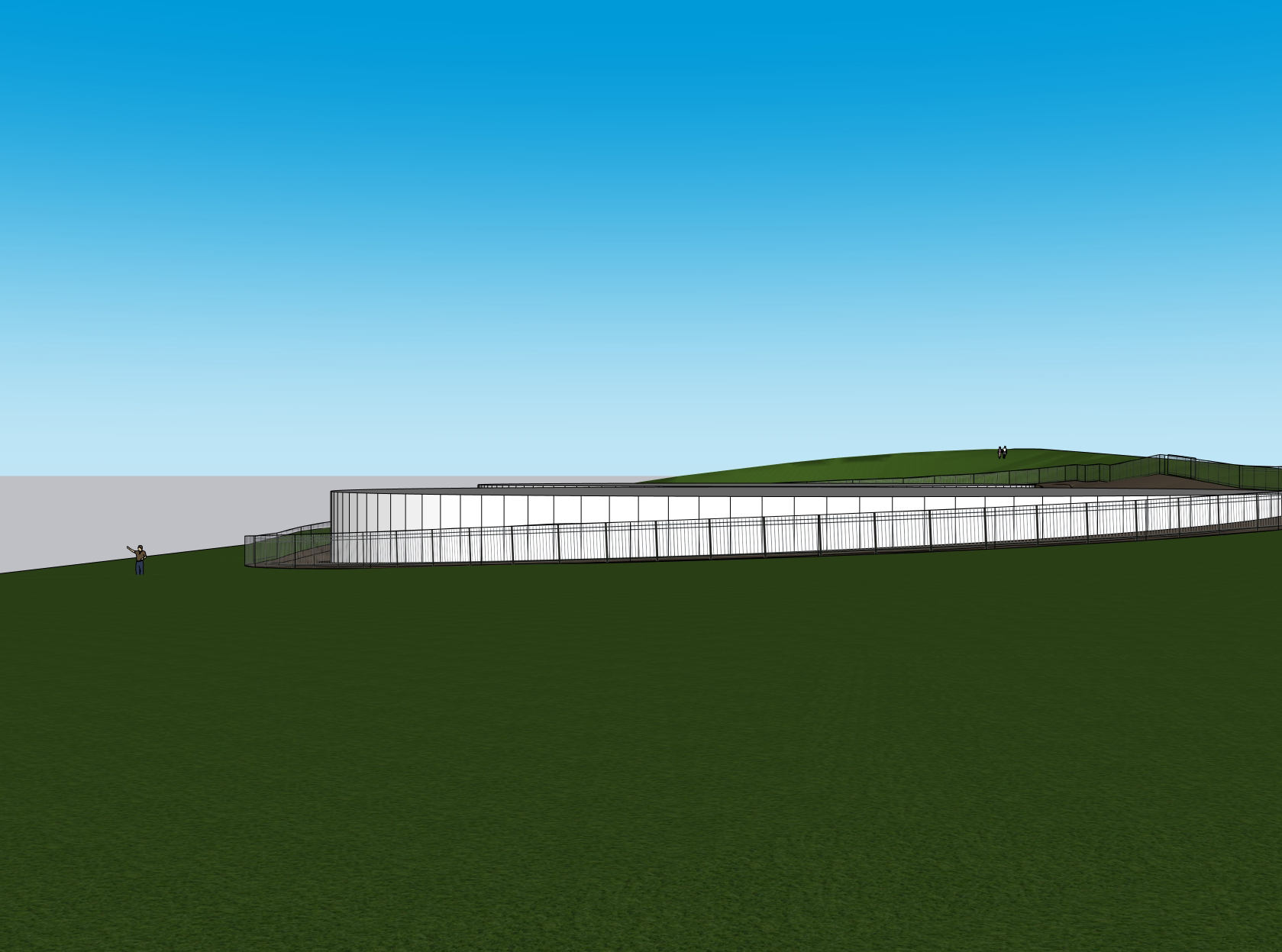

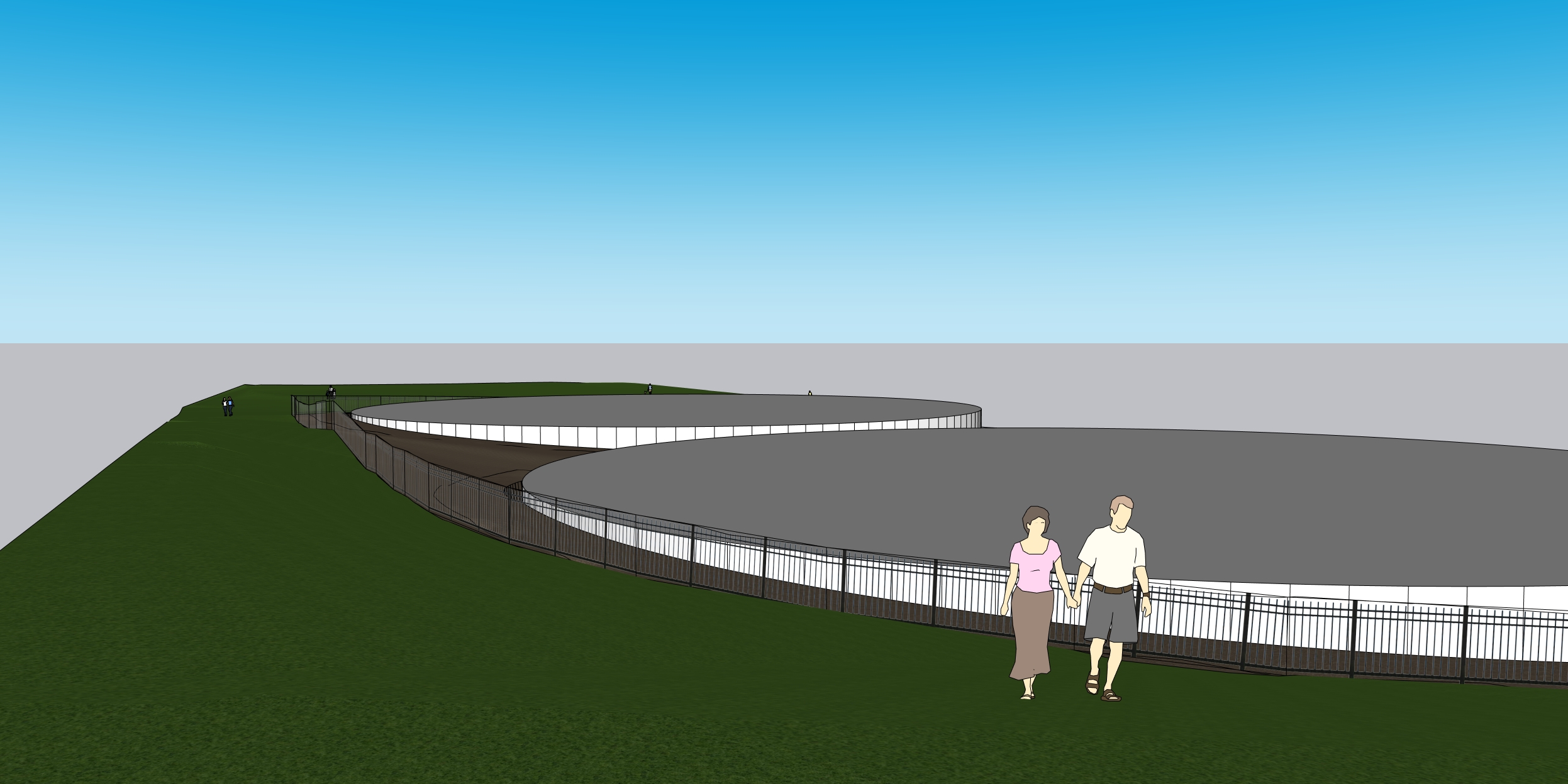

The replacement tanks were designed to sit 15 feet deeper than the existing reservoir to work hydraulically with other storage tanks in the system.

EWEB’s excavation contractor, Pacific Excavation Inc., dug multiple test pits in late September to field-verify the site conditions presented in the Geotechnical Investigation and Seismic Hazard Study that was prepared for this project. Approximately three feet under the surface, they hit rock that was not diggable with an excavator alone. This discovery presented the contractor with a choice:

- Equip excavators with rock teeth and hammers and attempt to chip out ~15 feet of rock mechanically.

-OR-

- Use controlled drilling and blasting to break the rock into smaller pieces that can be removed from the site.

To compare the options, our contractor did the following:

- Compared production rates (how long it would take to remove the required amount of material) between the two methods.

- Reviewed the geology of the site to determine whether controlled drilling and blasting could be accomplished within set regulations to protect surrounding structures and utilities.

The contractor found that:

- Controlled drilling and blasting could be designed and implemented while adhering to all regulations to protect surrounding structures.

- The use of controlled drilling and blasting would significantly expedite excavation, keeping the project on schedule and reducing the duration of excavation-related noise for neighbors.

Meeting with Vibration Expert, Dr. Chris Breeds

EWEB hosted our vibration consultant for this project, Dr. Chris Breeds, Ph.D., P.E., CEng., at the College Hill site on November 7 to speak with neighbors about the use of controlled drilling and blasting. Dr. Breeds confirmed the work would be conducted within existing regulations to protect existing structures and explained how vibration dissipates with distance. Below are two reference documents with additional information.

1) Guide to the Differences Between Blasting and Earthquakes (PDF)

2) White Paper on the Selection of Blast Vibration Criteria (PDF)

Regulatory Framework, Blast Design, and Safeguards to Protect Existing Structures

Controlled drilling and blasting is a common and safe method of excavation. EWEB is working with a qualified contractor, Aggregate Resource Industries (ARI), and vibration monitoring consultant, Dr. Chris Breeds, Ph.D., P.E., CEng., to design and execute the blasts. This team takes into consideration the entire surrounding area and all regulatory requirements in the blast design.

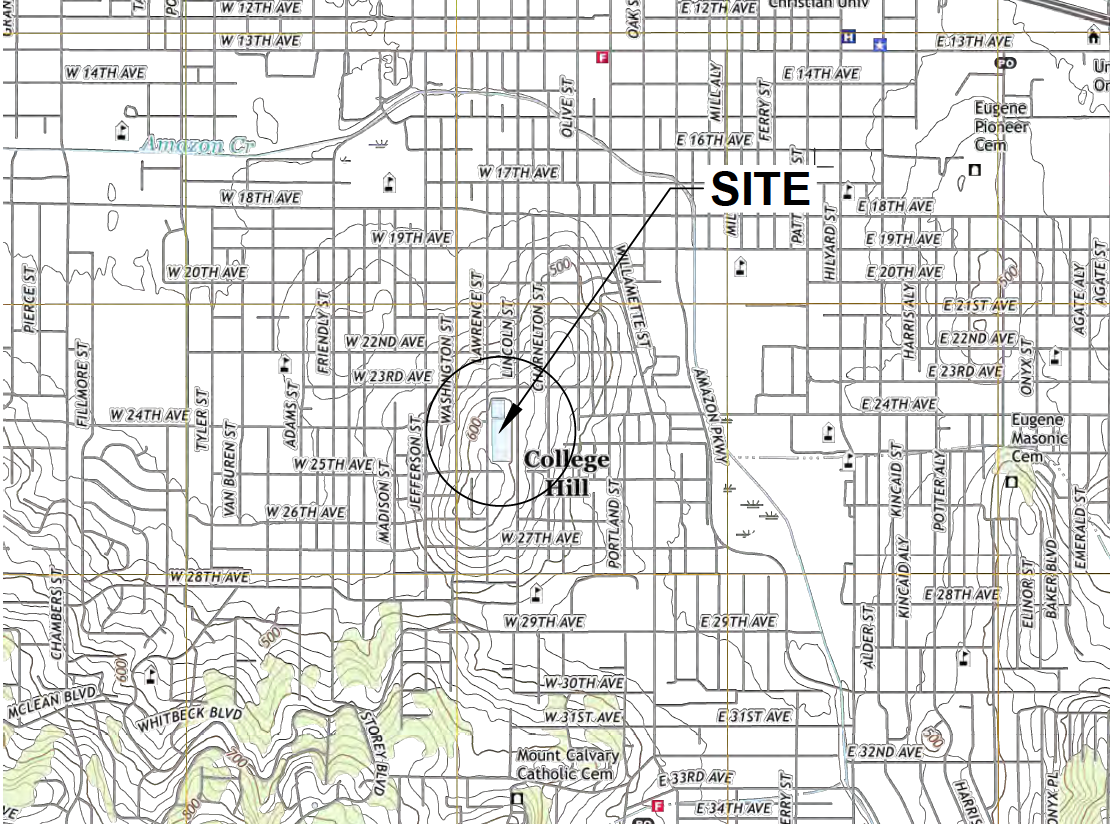

The excavation area (the footprint of the previous large, rectangular reservoir 607) will be split up into a grid of 24 sections. Each smaller section will be blasted separately to keep ground vibration and air overpressure below thresholds required to protect adjacent structures and utilities.

Thresholds for ground vibration and air overpressure are set by the Oregon State Fire Marshal in the National Fire Protection Association (NFPA) 495 standards. Each blast is designed to meet the requirements of NFPA 495 at the nearest structure and closest utilities.

Geotechnical Investigation and Seismic Hazard Study

Read the geotechnical investigation and seismic hazard study for this project.

Other Frequently Asked Questions

The use of controlled drilling and blasting is a safe and common method to fracture subsurface rock. Below is a summary of what you can expect. Please attend an upcoming meeting or reach out to the project team at water.storage@eweb.org if you have any other questions.

What is the general process for blasting?

The contractor will drill a grid of 3-inch holes drilled 6 feet apart. The drill rig will operate between 7 a.m. and 5 p.m. Monday – Friday. This is the loudest part of the process.

Explosives will be delivered to the site each morning. Once the explosives are onsite and the morning safety meeting is complete, the blasters will begin loading the holes with explosives and run wires to a central computer. Each hole is filled with rock to contain the energy and then blast mats are placed over all the holes included in the blast. The blast mats will extend 10 feet beyond each hole. The mats provide an extra layer of protection as each blast is designed to protect nearby structures without the use of the blast mats.

After the charges are all set and final checks are complete, the blaster in charge will begin the count down to the blast. An air horn will go off 5 minutes before, then 1 minute before, then they will yell fire in the hole and push the button. There will be an all-clear air horn after the blast.

When will drilling start?

Contractors may start drilling the week of November 11, but this might shift. Drilling is necessary to prepare the site for blasting.

When will blasting start?

Blasting is tentatively scheduled to start in mid-November. This is contingent on all the inspections for residents within 300 feet of the reservoir being completed, the floor slab being removed and holes being drilled. We will notify neighbors of the date of the first blast as soon as it is set. We should have a firm date to share about two or three days before the first blast.

What area will be blasted?

The entire footprint of the old large reservoir 607 will be blasted. The area will be divided into a grid and the blasters will work on one section at a time.

How many blasts will be required? When will they happen?

There will be 24 sections, each requiring one blast. The team will try to do one blast per workday. Every blast will occur as close to 1:30 p.m. as possible.

Each individual blast will last a few seconds. There will be an air horn that will go off 5 minutes before the blast, then again 1 minute before, and then you will hear the blaster in charge yell fire in the hole, then you will hear the blast, and then one final all clear air horn. The whole process, when everything goes as planned, is about 7 minutes.

Will blasts occur every workday once blasting commences?

The goal is for one blast to happen every workday (Monday – Friday) after the blasting phase commences to get through the 24 sections as quickly as possible. This schedule is contingent on the drill rigs being able to drill the holes for each section on schedule. Weather can also disrupt the blasting schedule.

Will Lincoln and Lawrence Streets be closed during the blasts?

Yes. Both Lincoln and Lawrence Streets between 23rd and 25th Avenues will be closed during the short time blasting is taking place each day. We are working with the city to determine a final traffic control plan.

How is the vibration from the blasts monitored?

Vibrations from the blasts will be monitored with seismographs, which will be set up around the site and surrounding area. The seismographs are solar powered and connected to the internet. They continuously monitor vibrations throughout the work and send blast reports immediately after the blast.

What will the blasting sound like?

The blasting will sound like a low loud rumbling.

I have a pet that is sensitive to loud noises; will the blasts be traumatic for them?

The blasts are less loud than fireworks and we have not had complaints about pets not handling the blasts well from other projects. We do suggest if you have sensitive pets to consider not being nearby during the blast.

How will the site be secured during blasting? Can I come to watch the blasting?

The road will be fully closed ahead of the blast and will be reopened after the blast is complete. There will be spotters on site to keep all people away from the property line and a safe distance from the blast zone. There WILL NOT be a viewing area that is open to the public during the blasting.

More Information About the College Hill Project

EWEB is replacing the leaky and antiquated reservoir with new, modern drinking water storage tanks built to withstand major earthquakes.

Learn more about the design of the new earthquake-resistant water storage tanks at College Hill.